Single Spindle Online Milling PCBA Depanelling Router

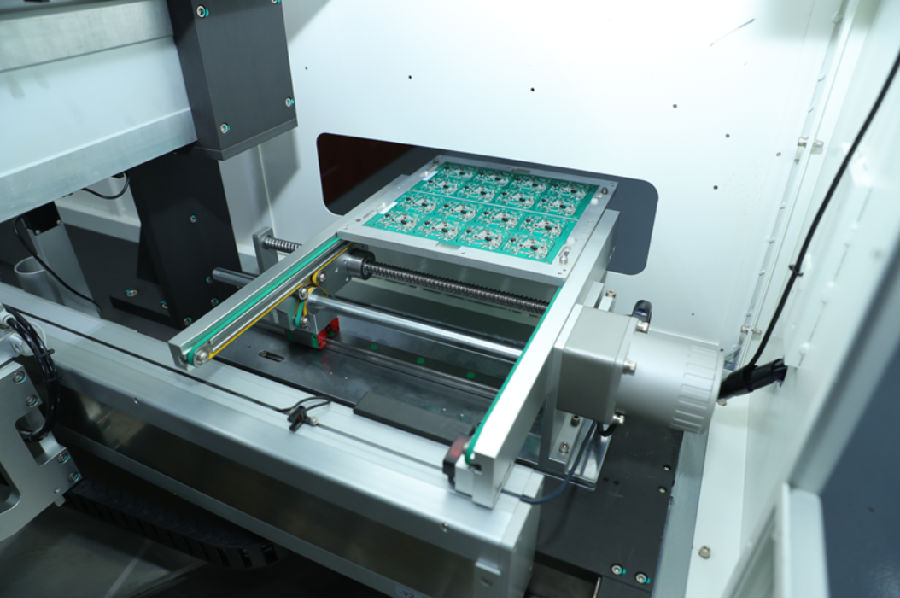

1. Clamp the product panel separation jig and place it on the processing platform for panel separation. After processing, clamp the panel separation jig again and place it on the track to flow into the next process.

(II): Put the special product panel fixture into the track

(III): Track-type discharge of special product panel separation jig

1. After the online automatic panel separation machine completes product cutting, the material removal clamp will clamp the entire product jig and place it on the discharge track for transportation to the next production process.

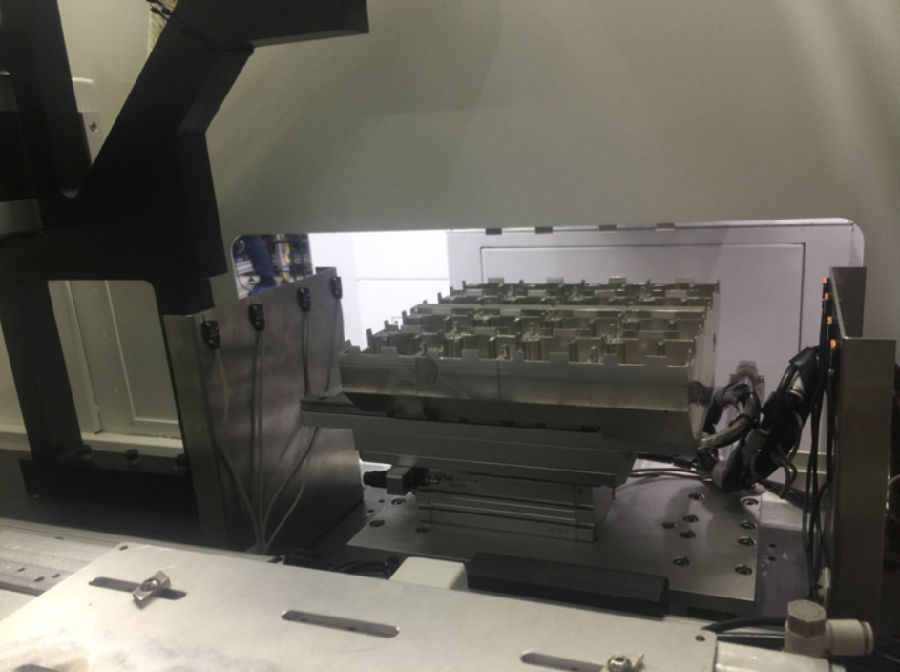

(IV): Automatic tool change method

1. Use German imported spindle for automatic tool change. Save time, realize automation, reduce human factors, high precision and strong stability

2. Built-in five sets of milling cutter magazine, convenient for automatic replacement of milling cutters and meet the needs of panel processing.

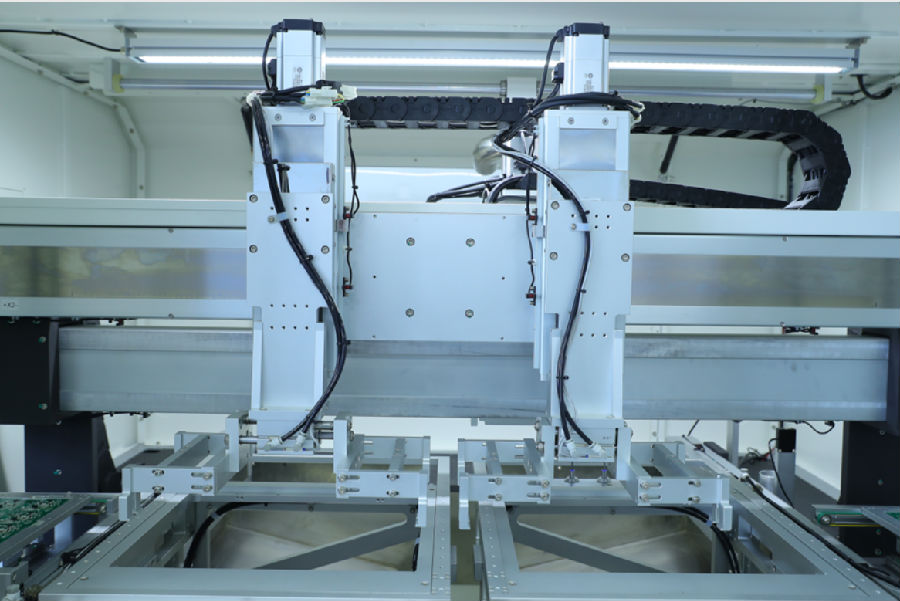

(V): Vacuum suction cup plate removal method structure

1. Pick-and-place device: automatic loading and unloading (modularized vacuum gripper, vacuum device, independently controllable)

2. Conveying structure: X2 axis moves Z2, Z3 axis suction, AC servo motor control.

3. Board picking speed: 0-1000mm/sec (adjustable)

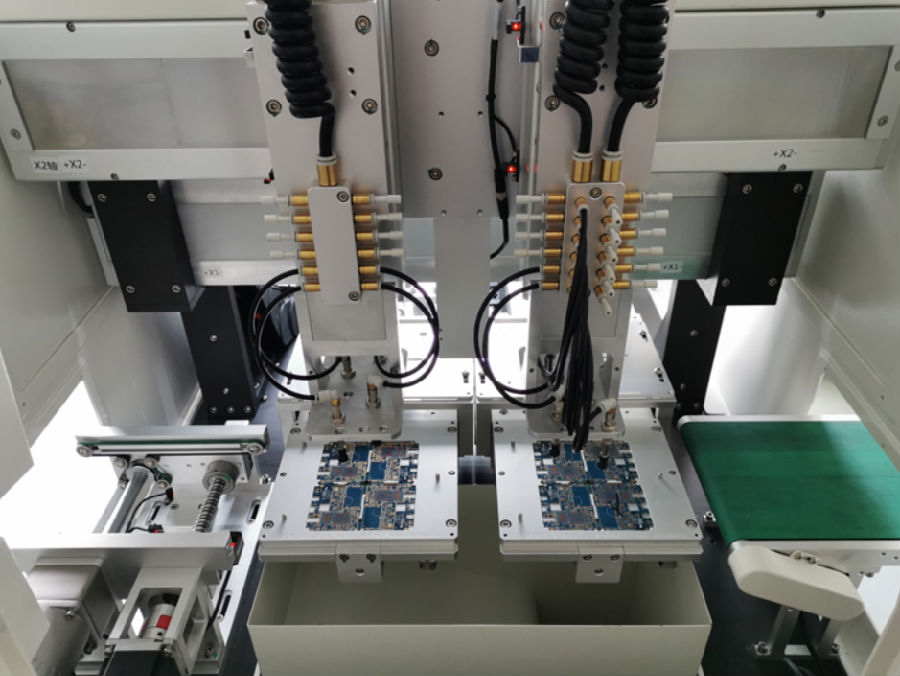

(VI): Special product fixture tray discharge method

1. The vacuum suction cup pick-up shaft vacuum absorbs the cut products at one time and places them on a special product fixture to transport them to the next production process.